Flexible PET Split Semi-Rigid Wrap Around Braided Sleeving

What is the Special of Split Braided Self Closing Wrap?

1. Semi rigid split braided sleeving is durable and lightweight for innovative solutions to cable management.

2. Protective cable socks are an ideal choice for lightweight bundling and organization.

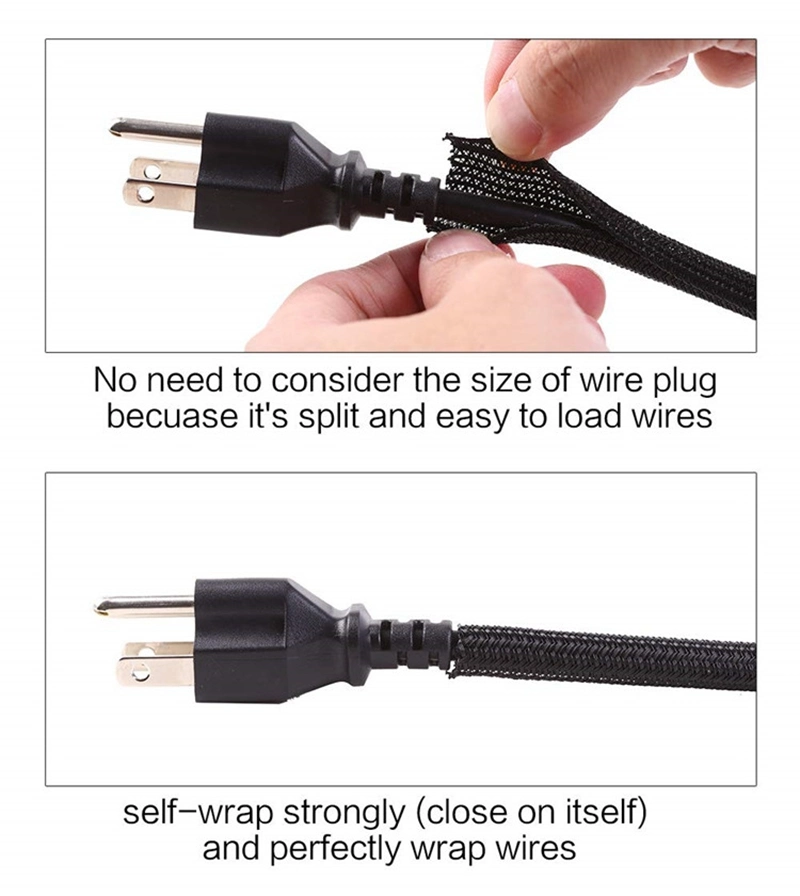

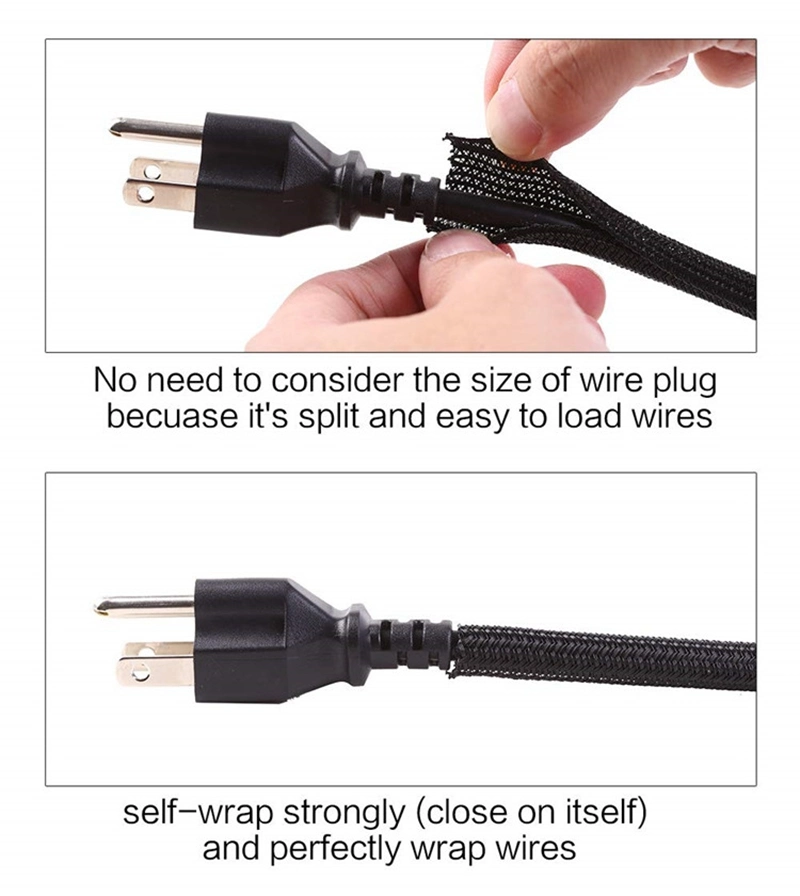

3. It offers protection against breakout areas while still allowing easy access to cables for inspection or maintenance.

4. The open structure design is built for simple installation after all other necessary components are configured.

5. Strong resilient force allows the wrap to keep cables from exposure, while providing excellent abrasion and flame resistance.

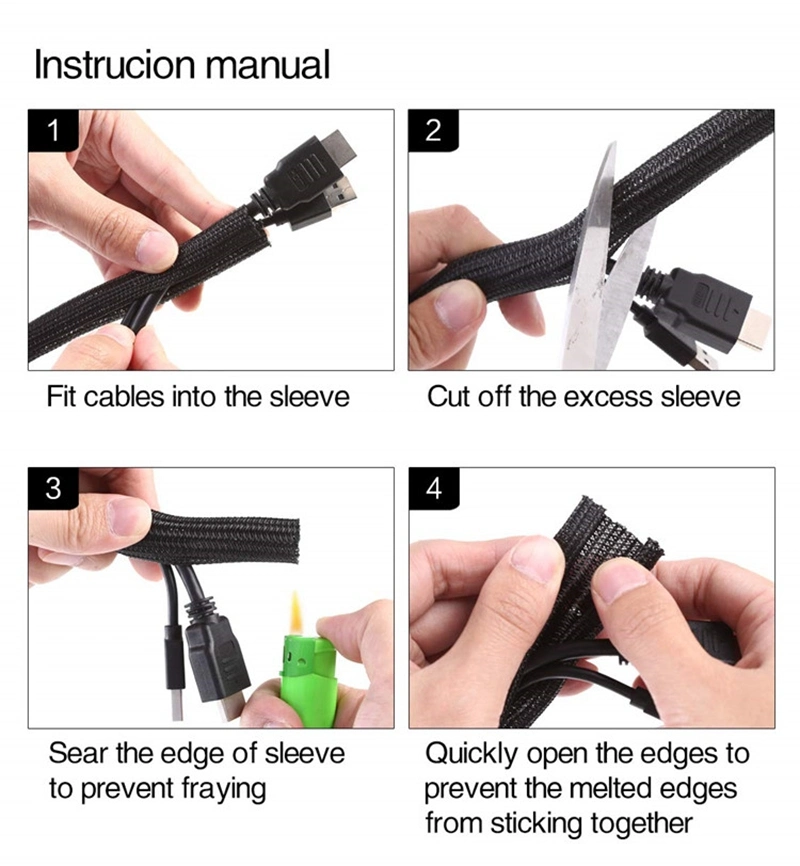

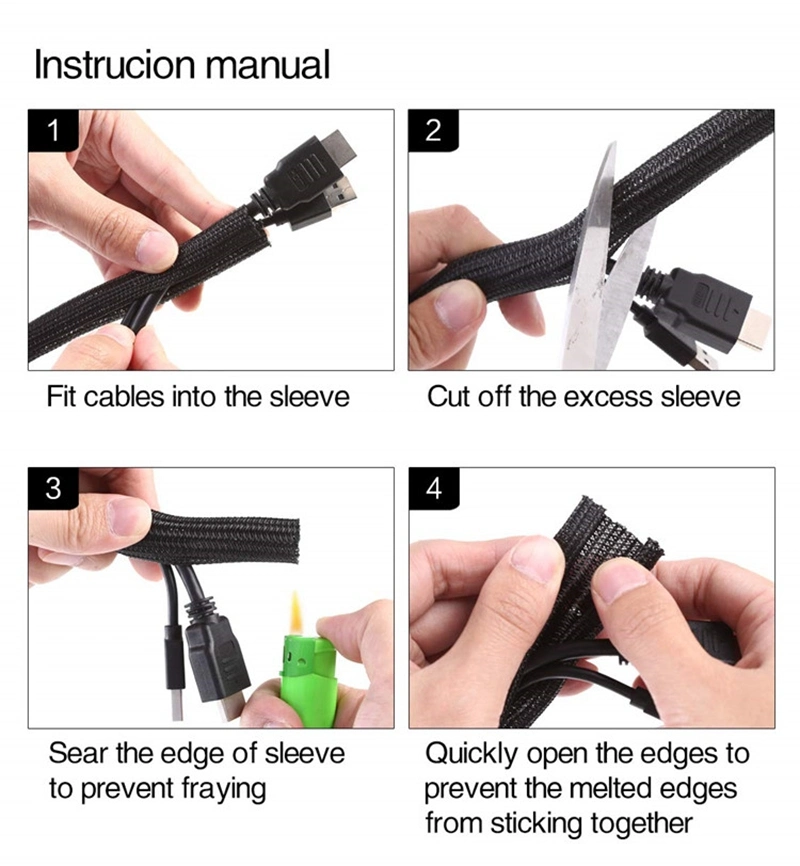

6. Trims to any length Using sharp scissors, you can cut the it to your desired length, to fit neatly under your desk or table,

or behind your media center.

7. Great on home theater wires, computers or gaming system components, even on small equipment hosing.

8. Continuous Operating Temperature of -50°C to 150°C

9. Melt Temperature of 240+(-)10°C

10. Halogen Free, UL, ROHS, REACH, CSA Approval.

What are the Details of Split Braided Self Closing Sleeve?

Application

Automotive wire harness, construction engineering, mechanical electronics, home appliance.

Widely used in high-speed rail, automotive, automation equipment, electrical wire of instrument, cable, flat wire harness and hose,

especially suitable for irregular shape wire harness.

Specification

Product Packaging

Company Profile

Production & Packing Process

Certifications

Delivery

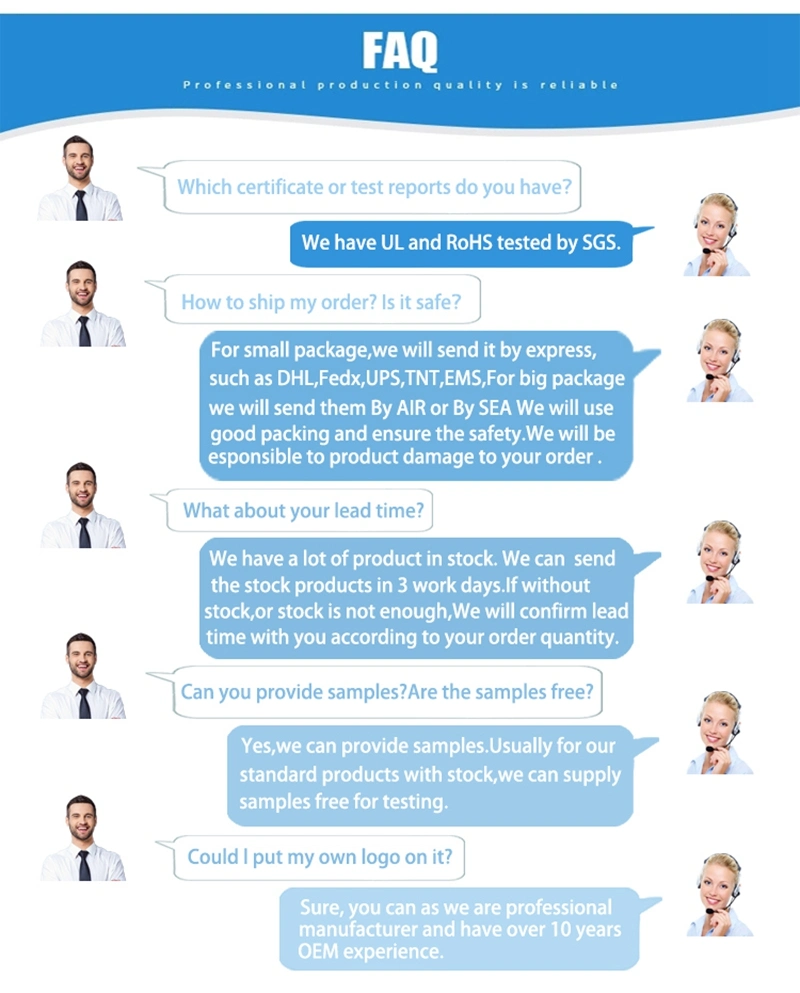

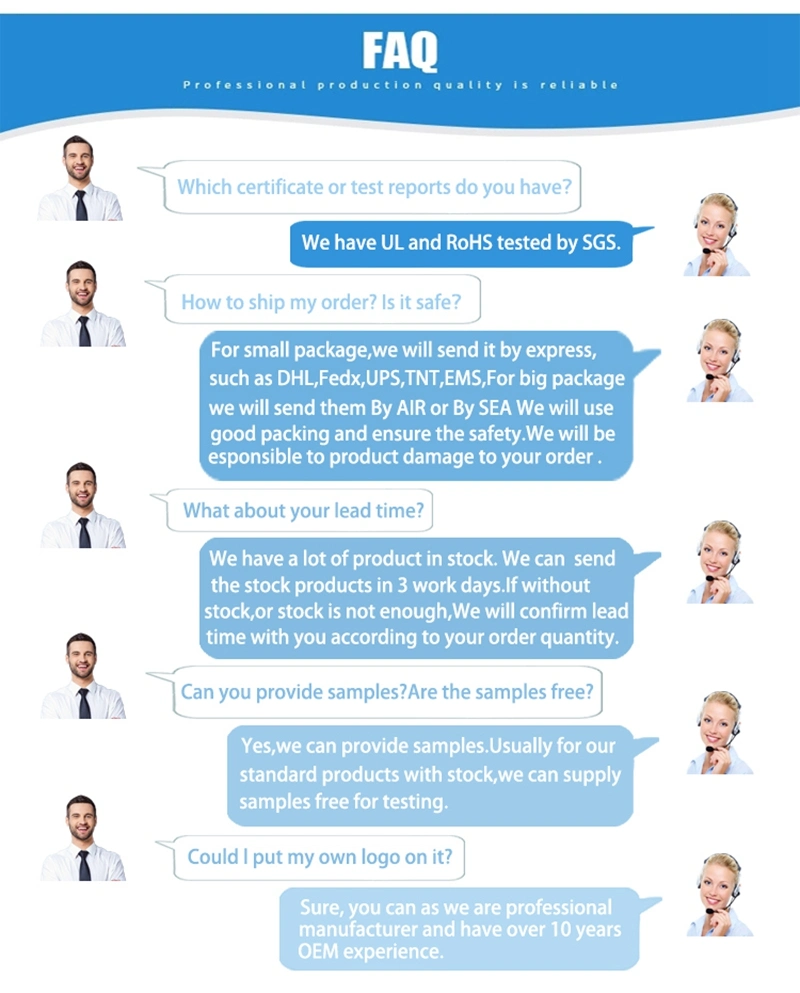

FAQ

What is the Special of Split Braided Self Closing Wrap?

1. Semi rigid split braided sleeving is durable and lightweight for innovative solutions to cable management.

2. Protective cable socks are an ideal choice for lightweight bundling and organization.

3. It offers protection against breakout areas while still allowing easy access to cables for inspection or maintenance.

4. The open structure design is built for simple installation after all other necessary components are configured.

5. Strong resilient force allows the wrap to keep cables from exposure, while providing excellent abrasion and flame resistance.

6. Trims to any length Using sharp scissors, you can cut the it to your desired length, to fit neatly under your desk or table,

or behind your media center.

7. Great on home theater wires, computers or gaming system components, even on small equipment hosing.

8. Continuous Operating Temperature of -50°C to 150°C

9. Melt Temperature of 240+(-)10°C

10. Halogen Free, UL, ROHS, REACH, CSA Approval.

What are the Details of Split Braided Self Closing Sleeve?

| Application | Great for automotive, computer and electronic, automatic equipment , railway wire harness and cable protection. |

| Material | Polyester Monofilament |

| Thickness | 0.25 or 0.38mm Monofilament |

| Overlap | 25% |

| Working Temperature | -50°C~+150°C |

| Melt Point | 240+(-)10°C |

| Flammability | UL94 V0 |

| Available Size | 6mm-50mm Inner Diameter |

| Standard Color | Black |

| Available Color | White, Grey, Blue, Green, Yellow or Customized |

| Cutting Tool | Hot Knife |

| Certification | ROHS, UL, CSA, REACH, Halogen Free |

| Cutting Tool | Hot Knife |

| Sample Lead time | As usual 3-7 working days |

| Production Lead time | 7~10 days |

Application

Automotive wire harness, construction engineering, mechanical electronics, home appliance.

Widely used in high-speed rail, automotive, automation equipment, electrical wire of instrument, cable, flat wire harness and hose,

especially suitable for irregular shape wire harness.

Specification

Part No | Size(ID) | Overlap | Max Bundle Dia | Packing |

MJ-SPBS006 | 6mm | 25% | 7mm | 100m/roll |

MJ-SPBS009 | 9mm | 10mm | 100m/roll | |

MJ-SPBS013 | 13mm | 14mm | 50m/roll | |

MJ-SPBS016 | 16mm | 17mm | 50m/roll | |

MJ-SPBS019 | 19mm | 20mm | 25m/roll | |

MJ-SPBS025 | 25mm | 26mm | 25m/roll | |

MJ-SPBS032 | 32mm | 33mm | 25m/roll | |

MJ-SPBS038 | 38mm | 40mm | 25m/roll | |

MJ-SPBS050 | 50mm | 52mm | 25m/roll |

Product Packaging

| Meter/Spool | 100m/spool, 50m/spool, 25m/spool |

| Spool/Ctn | 4 spools/ctn |

| G.W | 9~13 kg/ctn |

| Carton Size | 43*43*50cm, 43*53*58cm, 63*63*68cm |

Company Profile

Production & Packing Process

Certifications

Delivery

FAQ

Send Inquiry for Free Sample!